The use of Transmission Belts like Timing & Poly Belts has evolved from being used merely for Power Transmission to now being extensively utilised for more complex operations like Packaging, Labelling and even Haul-Off Applications.

To this end – namely achieving higher frictional properties, we need to coat the belt concerned with an extra layer of material such as Linatex Rubber, PU and Sponge to ensure better abrasion resistance.

Embekon Engineers (India) started Coated Belt operations at our plant in 2006 and since then has gained extensive knowledge and expertise in using a variety of coating materials as per customer requirements on any basic belt like Rubber & PU Timing Belts, Poly-V Belt, Flat Belt, etc.

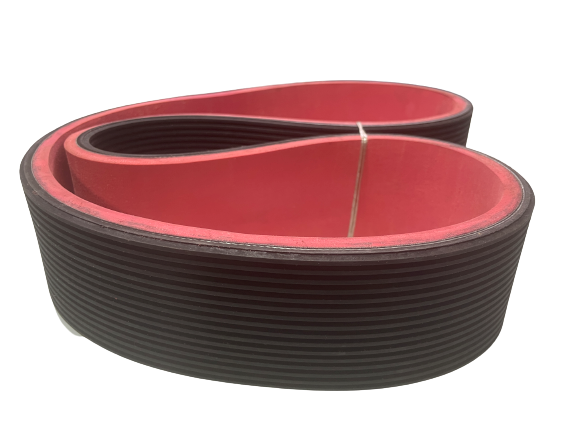

Rubber Coated Belts

Embekon Engineers (India) offers an extensive array of Rubber Coated Belts. We have moulds for a large range of Timing Belts and Feeder Belts where the coating is truly endless without joint.

We also manufacture a range of profiled Haul of Belts with top finishes as per the clients requirements. We use imported Poly-V Belts as the base for these belts and the coating is done in-house.

The rubber is made from our own in-house compound manufacturing facility and can be custom made to suit individual client requirements with regards to hardness, abrasion resistance and color. Our coated belts go through a rigorous process of quality checks right from raw material compound stage to finished product stage and are cleared only if it satisfies our standards.

Finish – Rough, Smooth, Textured Hardess – 35 Shore A to 55 Shore A.

Color – White, Red, Black

Usage

- Rubber Coated Timing Belts are commonly used in form fill seal machines to pull down plastic foils to form a pouch / bag into which the product to be packed is filled. Popular Industries are Packaging, Labelling, Food, Textile & Ceramics.

- Rubber Coated Nylon Sandwich Belts (Feeder Belts) are primarily used in corrugated paper industries and printing industries.