Timing Belts are a superior alternative to V-belts, Roller Chains and Gears in an amazing number of applications. Embekon Engineers deals in the entire range of Rubber and Poly-Urethane (PU) Timing Belts in standard and special widths and lengths. We stock Timing Belts of globally renowned brands thereby maintaining our focus on quality and ensuring customer satisfaction. The following are the various types and dimensions of Timing belts available in both Rubber and Poly-Urethane.

Synchro Power Timing Belts

A synchronous timing belt is a toothed belt, usually of reinforced rubber / poly-urethane that meshes with the grooves of a pulley in a synchronous belt drive. It usually drives the camshaft in an internal combustion engine. These belt drives, unlike flat and V-belt drives are positive and maintain constant speed during power transmission, thereby avoiding slippage. Synchronous Belts have a trapezoidal tooth profile. These belts are based on imperial (inch) as well as metric (mm) pitch sizes.

| ||||||||

| Type | Nomenclature | Pitch (Inch) | Pitch Pb | Tooth Height ht | Thickness hs | Tooth Angle ß | ||

MXL | Mini Extra Light | 0.080 | 2.032 | 0.510 | 1.14 | 40 | ||

XXL | Extra Extra Light | 0.125 | 3.175 | 0.760 | 1.52 | 50 | ||

XL | Extra Light | 0.200 | 5.080 | 1.270 | 2.30 | 50 | ||

L | Light | 0.375 | 9.525 | 1.910 | 3.60 | 40 | ||

H | Heavy | 0.500 | 12.700 | 2.290 | 4.30 | 40 | ||

XH | Extra Heavy | 0.875 | 22.225 | 6.350 | 11.20 | 40 | ||

XXH | Double Extra Heavy | 1.250 | 31.750 | 9.530 | 15.70 | 40 | ||

|

||||||

| Type | Pitch (Inch) | Tooth Height ht | Thickness hs | Tooth Angle ß | ||

|

T2.5 |

2.5 |

0.70 |

1.30 |

40 |

||

|

T5 |

5.0 |

1.20 |

2.20 |

40 |

||

|

T10 |

10.0 |

2.50 |

4.50 |

40 |

||

|

T20 |

20.0 |

5.00 |

8.00 |

40 |

||

|

AT5 |

5.0 |

1.20 |

2.70 |

50 |

||

|

AT10 |

10.0 |

2.50 |

5.00 |

50 |

||

|

AT20 |

20.0 |

5.00 |

8.00 |

50 |

||

High Torque Drive (“HTD”) Timing Belts

HTD timing belts are metric curvilinear tooth form synchronous belts for low speed high torque drives. HTD belts have a curvilinear tooth form giving a more uniform distribution of shear stresses within the teeth and a transition of tooth loads to the tensile members in the belt which significantly improves upon classical Timing Belts. These belts are based on the metric (mm) pitch sizes:

| |||||

| Type | Pitch Pb | Tooth Height ht | Thickness hs | ||

2m | 2.00 | 0.75 | 1.36 | ||

3m | 3.00 | 1.17 | 2.41 | ||

5m | 5.00 | 2.06 | 3.81 | ||

8m | 8.00 | 3.36 | 6.00 | ||

14m | 14.00 | 6.02 | 10.00 | ||

20m | 20.00 | 8.40 | 13.20 | ||

Super Torque Drive (“STD”) Timing Belts

Super-Torque Drive is a metric curvilinear pitch available in the following sizes:

| |||||

| Type | Pitch Pb | Tooth Height ht | Thickness hs | ||

S 2m | 2.00 | 0.76 | 1.36 | ||

S 3m | 3.00 | 1.14 | 2.20 | ||

S 4.5m | 4.50 | 1.71 | 2.81 | ||

S 5m | 5.00 | 1.91 | 3.40 | ||

S 8m | 8.00 | 3.05 | 5.30 | ||

S 14m | 14.00 | 5.30 | 10.20 | ||

Polyurethane Steel Cord Reinforced Timing Belts

|

Poly Urethane Timing Belts |

|||

| Type | Pitch Inch | Pitch mm | Thickness mm |

|

T2 |

0.079 |

2.000 |

1.10 |

|

T2.5 |

0.098 |

2.500 |

1.30 |

|

T5 |

0.197 |

5.000 |

2.20 |

|

T10 |

0.394 |

10.000 |

4.50 |

|

AT5 |

0.197 |

5.000 |

2.70 |

|

AT10 |

0.394 |

10.000 |

5.00 |

|

AT20 |

0.787 |

20.000 |

8.00 |

|

MXL |

0.080 |

2.032 |

1.20 |

|

XL |

0.200 |

5.080 |

2.25 |

|

L |

0.375 |

9.525 |

3.50 |

|

H |

0.500 |

12.700 |

4.30 |

Advantages of Rubber and PU Timing Belts

- No Lubrication Required

- High abrasion resistance

- 98% efficiency

- Exceptional resistance to flex fatigue

- Reduces Vibration and Noise

- Resistant to moisture, grease, oil, and gasoline

- Resistant to hydrolysis, ultraviolet light and ozone

- Linear Speeds up to 80 m/sec

Twin Tooth Timing Belts

These distinctive Timing Belts are recommended for synchronized serpentine drives where load transmission is required on both sides of the belt. It eliminates the noisy oily chain drives and offers a long virtually trouble free service in wide horsepower range. They are specified the same way as timing belts except with a “D” prefix. Double sided timing belts are available in the following series: DXL, DL, DH, DT5 and DT10. Open ended belts in some of these series available on request.

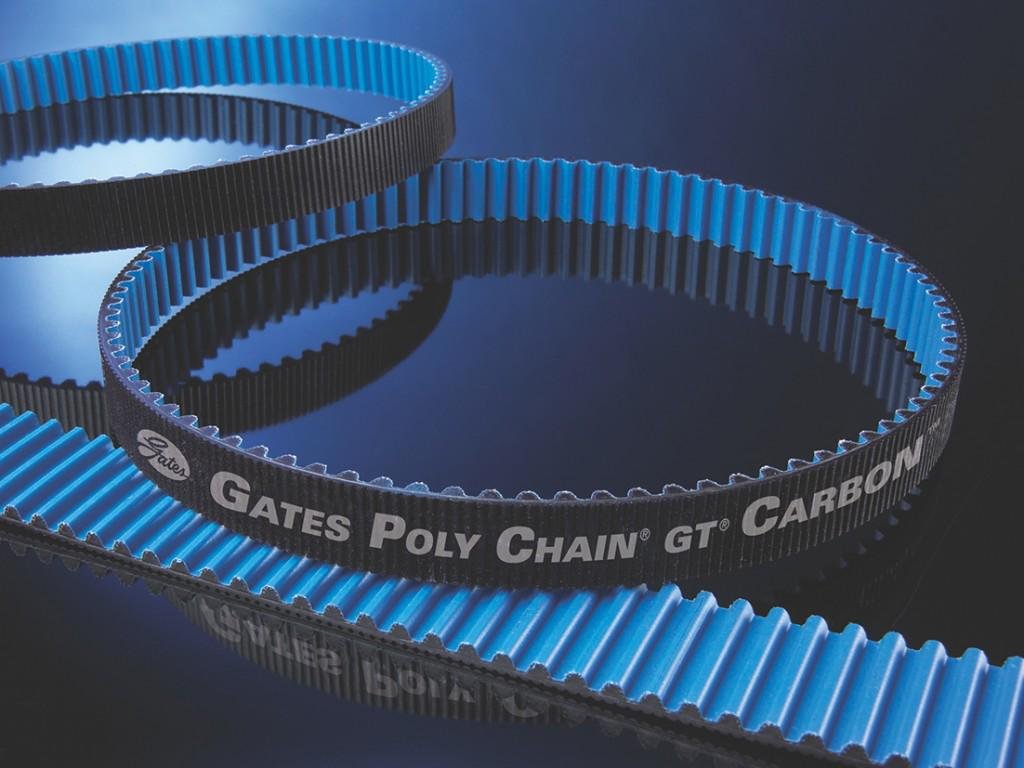

Gates Poly Chain® GT® Carbon™ Belts

Poly Chain® GT® carbon Belts provide positive trouble free power transmission in low speed high torque applications. Gates Poly Chain® GT® Carbon™ belt is part of a powerful synchronous belt drive system that outperforms roller chain in even the most demanding high-torque applications. These belts are available in 8mm and 14mm pitch sizes.

We deal in Timing belts of leading brands like Mitsuboshi, Gates, Optibelt and Continental Contitech. We offer a wide selection of Timing Belts to fulfill the dynamic power transmission requirements of our customers. Special widths are cut to order from our sleeve stock for fast delivery.

Application

Timing belts play an important role in tooling machinery, textile machinery, medical equipment, vending machinery, garden machinery, household electrical appliances, measuring instruments, automobiles, food processing machines and printing machines.